Service

Rubber

Value-Added Rubber Lining Installation Service

RCM provides an effective solution for industrial equipment that requires rubber lining. Whether for piping, tanks, boiler components, or chutes and transfer points, rubber lining significantly extends equipment lifespan by protecting against abrasion, corrosion, and erosion.

To meet complex operational needs, RCM offers on-site lining and repair services. This added value, along with our commitment to recycling and revalorizing used rubber, makes our offerings distinctive.

Rubber Lining Installation

On-Site and Factory Options

Our rubber lining installation process applies to all types of equipment. RCM’s experts can recommend the best rubber type based on resistance levels to abrasion, high temperatures, oxidizing acids, and more. Rubber can be either autoclaved or cured atmospherically, as per manufacturer specifications. Installations can be completed either at our facility or on the customer’s site.

Extraction of Used Rubber for Reconditioning

On-Site and Factory Options

RCM provides an equipment refurbishment service, involving the removal of used rubber before installing new linings. This process can be performed on-site or at our facility, depending on the equipment type. By extending equipment life, this service also helps reduce procurement costs. The process includes inspection, extraction, surface preparation, rubberizing, curing, finishing, and final inspection.

Field Repairs

On-Site and Factory Options

Our team can perform targeted repairs on equipment that does not require a full rubber lining replacement, minimizing travel costs and production downtime. Experts arrive equipped with the necessary materials and tools to address specific repair needs, thereby prolonging equipment life.

Used Rubber Recycling

Circular Economy Commitment

In line with our commitment to the circular economy, RCM fully recycles used rubber extracted from equipment. We employ a safe method to transform rubber into a fine powder, optimized for seamless integration with virgin rubber compounds. This enhances contact surface area, mitigating many industry challenges and facilitating the production of TPV and other recycled rubber products.

Available Lining Materials

RCM’s experts will assist you in selecting the most suitable material based on your needs and the specific conditions of your equipment. Our offerings include:

Flexible Rubber Linings:

Soft rubbers that resist abrasion and many chemicals, ideal for water treatment and HCL applications.

Semi-Hard Rubber Linings:

Designed for strong acids at high temperatures and wet chlorine, with excellent adhesion to steel.

Chlorobutyl Linings:

Resistant to ozone, sunlight, and various acids at temperatures up to 200°F.

EPDM Linings:

Highly resistant to chemicals, sunlight, and oxidizing conditions, suitable for use at temperatures up to 200°F.

Nitrile Linings:

Ideal for oil resistance and abrasion, performing well at temperatures up to 200°F.

PVC Linings:

Flexible and impermeable, effective for containing chemicals, liquids, or waste, available in thicknesses from 0.02 to 0.04 inch.

General Steps for Extracting and Installing Rubber

Removal of used rubber

Inspection, sanding, and surface preparation

Installation of rubber lining

Atmospheric or autoclave curing

Painting, finishing, and final inspection

Our customer

Petrochemicals

Chemical

Railway

Mining

Food

Civil

PROJECT PRESENTATION

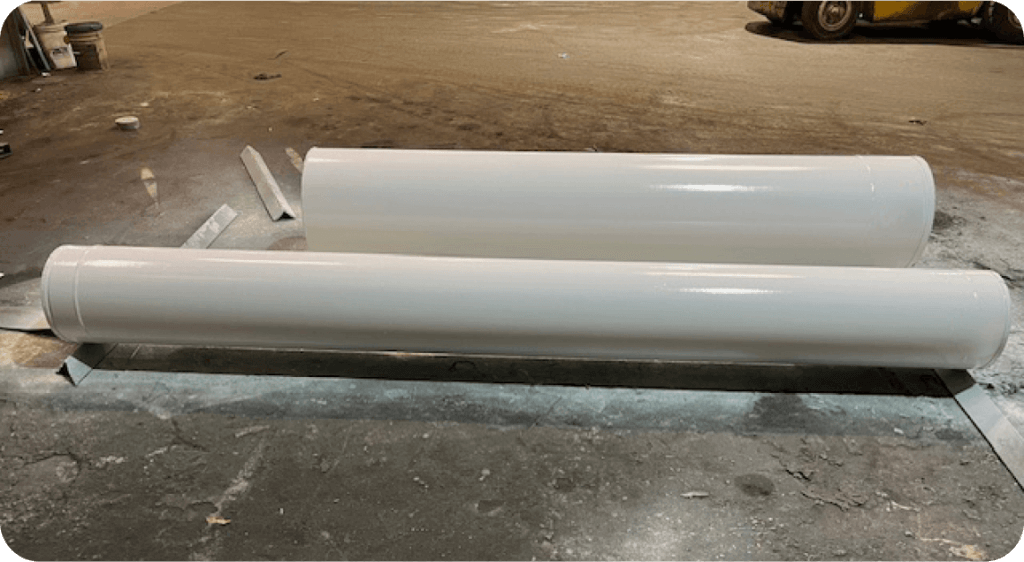

Refurbishment of mining steel pipes used to transport concentrator tailings

Mining industry | Piping for concentrator tailings

In this project, RCM offered a solution to the mining company’s problem: the steel pipes used to transport the concentrator’s tailings were worn. Rather than send large quantities of pipes to landfill, the RCM team carried out a multi-stage refurbishment, including both rubber and steel components.

The refurbishment began with a complete inspection of the steel pipes, inside and out, to detect any breaks requiring repair. Worn-out rubber was removed to be 100% recycled into fine powder. Damaged steel sections were cut, recycled, and replaced with new ones.

The steel pipes were then sandblasted and cleaned, inside and out, in preparation for the finishing stages. The new rubber lining was installed and autoclaved according to the manufacturer’s specifications, before being finished off with an exterior paint adapted to the application.

The mining company was satisfied with the result and was able to reintegrate the refurbished pipes into its production cycle, thus limiting the cost of sourcing new equipment and reducing the amount of scrap sent to landfill sites.

Before

After

FAQ

Lorem ipsum dolor sit amet consectetur.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum amet consectetur.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.