Service

Metals

Recycling, cleaning and resale of metal products

RCM also offers a metal recycling service, helping to keep metals out of landfill sites and reintegrating them into the production cycle. The metals come from a variety of industries, including foundries and steel mills. Items processed include cast iron and steel skulls, steel slag, slide gates, electrodes, and anodes. RCM also uses particle size reduction equipment with a screening system tailored to customers’ specific needs.

Skulls, slag, electrodes, and anodes

Processing involves cleaning metals heavily contaminated with impurities through various mechanical stages of grinding and separation of magnetic and non-magnetic elements. The cleaned product can then be returned to customers, i.e. steel mills and foundries, for re-integration into castings.

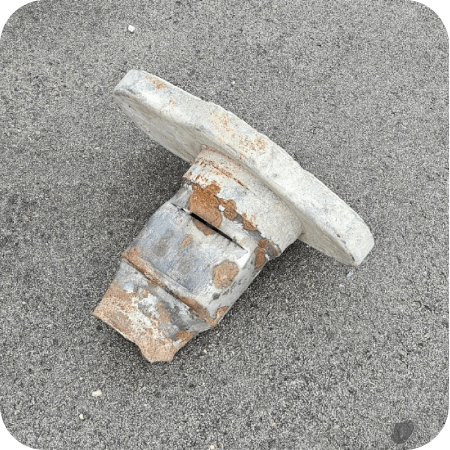

Slide gates

Slide gates benefit from a specific technology developed by RCM, which allows the alumina to be extracted and separated from the steel part. It is therefore possible to separate alumina from the nozzle, as well as from the base plate.

Available recycled products

Graphite powder

Alumina

Carbon anodes

Carbon powder

Our customer

Steelworks

Foundry

Refractory industry

PROJECT PRESENTATION

Separation of refractory materials and steel for complete recycling of slide gate valves

Steelworks | Ladle slide gate refractories

For this project, RCM offered a solution for the separation and recycling of all slide gate materials, i.e., steel and refractory materials, the latter varying according to the manufacturer.

Once the valves had been received in bulk, the first step was the mechanical separation of their two main parts: the base plate and the nozzle (or sleeve). The second step was to separate the refractory materials from the steel of the nozzle and base plate.

Finally, the refractory materials underwent various cleaning, granulation, decontamination, screening, and bagging processes, all according to the customer’s specifications and requirements. The steel was sent directly to the steel mills for melting.

The customer was satisfied, and the project prevented a large quantity of material from being sent to landfill sites, as well as ensuring its reintegration into a new use, depending on its nature.

FAQ

Lorem ipsum dolor sit amet consectetur.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum amet consectetur.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.